In manufacturing, few challenges are as demanding as producing millions of identical components, each meeting exact specifications, without sacrificing speed or breaking the budget. For industries from automotive to electronics, this high-volume puzzle requires a specific solution. That solution is production stamping.

This manufacturing process is the backbone of mass production, transforming rolls of metal into vast quantities of finished parts. Production stamping offers a unique combination of velocity, consistency and economy that is difficult to match with other methods. Let’s explore how this established technology continues to empower manufacturers to meet relentless market demands, uphold strict project timelines and satisfy stringent quality requirements.

The Engine of Mass Production

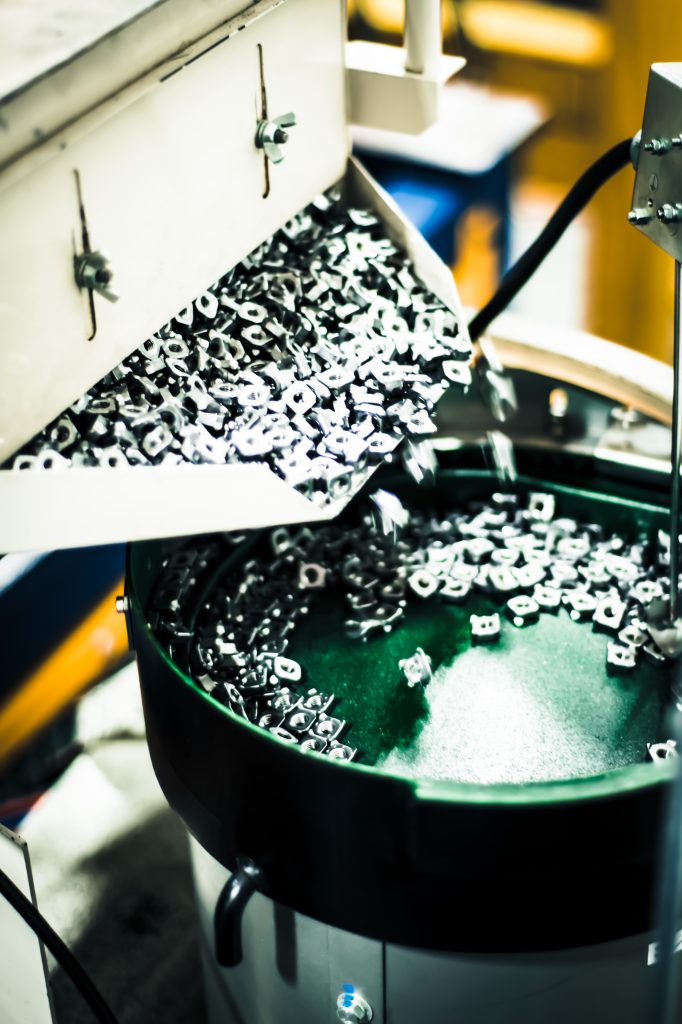

At its heart, production stamping is a cold-forming process that uses dedicated presses and tooling to shape and cut metal. A press drives a tool and die system to stamp, punch or bend metal sheets into a desired form with remarkable speed. What truly sets high-volume stamping apart is its ability to perform these operations continuously, often for days, with minimal interruption. This creates a steady, predictable flow of components that keeps assembly lines moving.

The process shines in its application of specific techniques designed for scale:

- Progressive Die Stamping: Imagine a metal strip feeding through a series of stations, each performing a small operation (piercing, bending, coining) until a finished part emerges at the end. This method functions like a manufacturing assembly line within a single press, achieving speeds of up to thousands of parts per minute and serving as the foundation for high-volume output.

- Transfer Die Stamping: For larger, more complex components like automotive structural elements, transfer stamping is often the answer. This method uses a mechanical system to pick up a part and move it between different presses or stations, with each station performing a specific operation. This allows for the manufacture of substantial parts that cannot be accommodated in a single progressive die.

- Deep Drawing: This process is specialized for creating hollow, cup-like forms such as fluid reservoirs or enclosures. A sheet metal blank is drawn into a die by a punch, forming a three-dimensional shape whose depth often exceeds its diameter. This requires particular skill in controlling material flow to prevent thinning or tearing.

Selecting the right technique is a strategic decision, balancing factors like part geometry, material type and the required production volume to achieve the most efficient outcome.

The Tangible Benefits

The advantages of production stamping extend far beyond rapid output. Its integrated benefits create a compelling case for its use in high-volume scenarios.

- Significant Cost Efficiency: While the initial investment in tooling can be substantial, the cost per piece becomes incredibly low over a long production run. This economy of scale is a fundamental advantage. Stamping also minimizes material waste through intelligent part nesting and design, and its high speed reduces labor costs per unit, delivering better value with every part produced.

- Consistency and Repeatability: In sectors like automotive and aerospace, a microscopic deviation in a component can lead to significant performance issues. Production stamping, once the tooling is perfected, guarantees that every part is a perfect duplicate of the last. This repeatability is maintained through rigorous quality control measures, including regular inspections and real-time monitoring systems, which verify part geometry and detect subtle process shifts long before they result in non-conforming products.

- Material and Application Versatility: Production stamping is not limited to a single type of metal. The process capably handles a wide spectrum of materials, including various grades of steel, lightweight aluminum, highly conductive copper and corrosion-resistant brass. This flexibility allows manufacturers to select the ideal material for a part’s function, whether it needs high strength for an automotive chassis, light weighting for an aerospace component or electrical conductivity for an electronics connector.

What Makes Consistent High-Volume Output Possible?

Achieving millions of cycles without faltering does not happen by accident. It relies on several key pillars that support the entire operation.

- Expert Tool and Die Design: The heart and soul of any stamping operation lies in its tooling. The design, engineering and construction of the dies determine the quality and efficiency of the entire process. Dies are typically crafted from specialized tool steels chosen for their hardness and wear resistance, allowing them to withstand millions of cycles. A well-maintained die is a reliable die, which is why proactive tooling management (including routine inspection, sharpening and preventive maintenance) is non-negotiable for avoiding unplanned stoppages.

- The Strategic Role of Automation: Modern production stamping facilities are highly automated environments. Robotics handle repetitive tasks such as loading raw materials, transferring parts between stations and unloading finished products. This integration does more than just speed up the process; it enhances worker safety by removing them from hazardous areas and drastically reduces the potential for human error, leading to more uniform output. Automated systems can maintain a pace and consistency over long periods that would be impossible to achieve manually.

- A Data-Driven Approach to Maintenance: The biggest threat to a high-volume production schedule is unplanned downtime. A reactive approach to maintenance, fixing machines only after they break, can bring a multi-million dollar operation to a halt. Leading manufacturers now employ predictive maintenance strategies, using sensors and data analytics to monitor equipment health. This allows them to identify a potential issue, like a slight increase in motor vibration or temperature and address it during a scheduled maintenance window, thereby preventing a catastrophic failure and the costly downtime that follows.

Meeting Industry-Specific Challenges Head-On

Production stamping is not a one-size-fits-all solution; its true power is revealed when its capabilities are directed toward the unique needs of a specific sector.

- Automotive Manufacturing: The automotive industry is a prime consumer of stamped parts, with thousands of metal components in every vehicle. From the underlying brackets and clips to visible body panels and structural elements, production stamping delivers the volume and consistency required. The industry’s shift toward lighter vehicles has also increased the use of aluminum alloys in stamping processes to reduce weight without compromising safety or performance.

- Electronics and Appliances: This sector demands a different kind of precision, often involving small, intricate parts like electrical connectors, shielding and frames. Stamping manufactures these components with the tight tolerances necessary for them to function perfectly in circuit boards and electronic assemblies. The process is also widely used to produce the internal structural components and enclosures for household appliances.

- Aerospace and Medical Devices: In these fields, the margin for error is effectively zero. Components for aircraft control assemblies or medical devices must perform flawlessly under extreme conditions. Production stamping, governed by strict quality standards like AS9100 for aerospace and ISO 9001 for quality management, provides the documented consistency and material traceability that these high-stakes industries depend on.

The Regal Metal Products Approach

For over five decades, Regal Metal Products has built its philosophy around the principle that quality is a culture, not just a department. We understand that our role extends beyond being a supplier; we function as an extension of our clients’ engineering teams. This partnership begins with early involvement in the design phase, where our experience can help refine a component for better manufacturability and cost-effectiveness.

We invest in a skilled workforce, with machinists and toolmakers who have dedicated their careers to mastering their craft. This human expertise, combined with our modern equipment and a deeply embedded quality system, creates a foundation for delivering parts that our clients can trust, run after run. We measure our success not just by the parts we ship, but by the smoothness of our clients’ production lines and their confidence in a timeline met.

Conclusion

In an economic landscape that prizes both scale and specification, production stamping remains an indispensable manufacturing discipline. It is a powerful answer to the complex challenges of high-volume production, offering a proven path to achieving cost targets, maintaining product quality and fulfilling ambitious delivery schedules. For businesses looking to navigate the demands of modern manufacturing, mastering the art and science of production stamping is a necessity.